1.EPS Cement Sandwich Panel

1).Product Composition

Surface :fiber cement board/calcium silicate board

Interior filling materials: EPS / cement / fly ash / sand / additive

2).Parameter and Index

| Item | Parameter and Index | ||||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 1 | Anti-impact capacity/times | ≥5 | ≥5 | ≥5 | ≥5 | ≥5 | ≥5 |

| 2 | Anti-bending damage load/times over deadweight | ≥3.0 | ≥3.0 | ≥3.0 | ≥3.0 | ≥5.0 | ≥5.0 |

| 3 | Compressive strength/Mpa | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 |

| 4 | Softening coefficient | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 |

| 5 | Surface density(kg/m2) | ≤70 | ≤70 | ≤90 | ≤90 | ≤110 | ≤110 |

| 6 | Moisture rate(%) | ≤10 | ≤10 | ≤10 | ≤10 | ≤8 | ≤8 |

| 7 | Dring shrinkage value(mm/m) | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| 8 | Hang force(N) | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1000 |

| 9 | Sound insulation capacity in the air(dB) | ≥35 | ≥35 | ≥40 | ≥40 | ≥45 | ≥50 |

| 10 | Fire endurance(h) | ≥1.5 | ≥1.5 | ≥2.5 | ≥2.5 | ≥3.0 | ≥4.5 |

| 11 | Heat transfer coefficient(w/m2.k) | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| 12 | Inner radiation index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 13 | Outer radiation index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 14 | Frost resistance(shall show no visible cracks and surface without change) | _ | _ | shall show no visible cracks and surface without change | |||

| 15 | The combustion properties(A1 or A2) | _ | _ | A1 or A2 | |||

3).Advantages

| Features | More Detail | ||||||||||||

| 1 | green | 100% free of harmful substances and are of A non-radioactive products, 100% Non-asbestos. | |||||||||||

| 2 | lightweight economic | The volume-weight only 750-800kg/m3 , the weight of 75mm thickness ZJT board is 54kg/m2, equal to 1/6 of brick weight, 1/7 of 120mm thickness masonry. | |||||||||||

| 3 | increase valid space | the thickness of ZJT wall decreases 85mm by using 75mm thickness ZJT boards. Thus, valid space increases 1/m2 per 11.8mm. in other words, it can increase 6/m2 per 100/m2 . | |||||||||||

| 4 | moistureproof waterproof | will keep dry and leave no stains. During humid days, the boards will not condense water either. suitable to be installed in such wet areas as kitchens, bath rooms, basements because of its moistureproof and waterproof. | |||||||||||

| 5 | fireproof | Fireproof limit of ZJT boards is more than 4 hours and does not emit toxic gases under 1000 degree. The nonflammable performance reaches national A-class standard. | |||||||||||

| 6 | heat insulation | ZJT board is composed of special material to keep heat and thermal within a favorable condition. At same time, the ZJT boards are able to adjust moisture automatically and keep moisture at a balance level. | |||||||||||

| 7 | sound insulation | The raw materials of ZJT boards have good performance in sound insulation. ZJT board with 90mm thickness gains sound insulation of 42dB. | |||||||||||

| 8 | walls can be nailed and grooved | ZJT board can be grooved to have conductor arrangement or nailed to hang heavy object. The surface of ZJT board is smooth enough to make finisher processing directly with tile, wall trim and so on. | |||||||||||

| 9 | good integration | By using steels at the joints, the strength of walls is high enough to do partition in large story height and long span structures and it anti-seismic performance is several times higher than masonry. | |||||||||||

| 10 | easy and fast construction | It can be cut to adjust length and width at will. The process of installation is easy and fast, without the need of pl | |||||||||||

2.Specification and Application

| Length | 2270mm, 2440mm | |||||

| Width | 610mm | |||||

| Thickness | 60mm | 75mm | 90mm | 100mm | 120mm | 150mm |

| Weight | 40KG/m2 | 54KG/m2 | 60KG/m2 | 67KG/m2 | 74KG/m2 | 107KG/m2 |

| Partition | roof | roof | interior wall | interior wall | exterior wall/ floor | exterior wall |

Application: residential building,school,hospital,villa,hotel,public construction,prefab house,shopping mall.

Other Application: super high wall,abnormity wall,pipe,fire well,equipment partiton

3.Installation

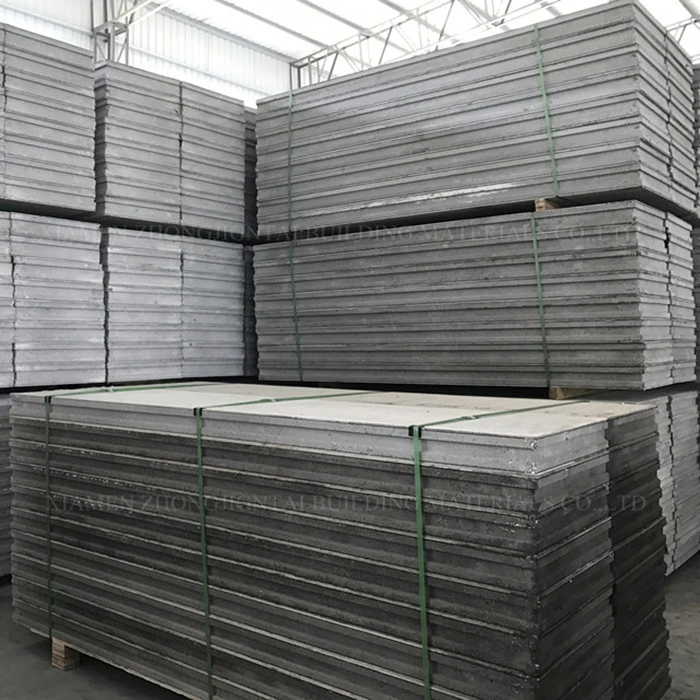

4.Packaging and Loading

| 2270 Mode | Load by 40'HQ | 2440 Mode | Load by 40'HQ |

| 2270*610*60mm | 636m2 | 2440*610*60mm | 607m2 |

| 2270*610*75mm | 524m2 | 2440*610*75mm | 500m2 |

| 2270*610*90mm | 411m2 | 2440*610*90mm | 393m2 |

| 2270*610*100mm | 374m2 | 2440*610*100mm | 357m2 |

| 2270*610*120mm | 337m2 | 2440*610*120mm | 322m2 |

| 2270*610*150mm | 262m2 | 2440*610*150mm | 250m2 |

XIAMEN ZHONGJIGNTAI BUILDING MATERIALS CO.,LTD

Adress: Unit 2A, Lianchang Building, NO.6-8 Huli Avenue, Huli District, Xiamen, China

Website: http:// zjteps.en.made-in-china.com

Our Project

6.FAQ

Q: What's included in the service range and what the core value of it is?

Our service mainly refers to quality products, good service for resourcing, inspection, shipment loading, and installation guidance. The core value is "sincere one stop solution for client's projects and requests".

Q: What's your price level compared with the quality you supplied ?

There are many kinds of quality level in China, which brings about price difference. Offering right quality for clients' markets and state quality honestly, our price is reasonable and acceptable for the long term business cooperation.

Q: What's your offer validity period?

Price offered by our company will be good for 2-5 working days upon quotation email sent.

And we'll keep you updated timely.

Q: How's your shipping service?

We can do both FCL shipping and bulk vessel shipping. We have good ocean freight offer as we're cooperating with the shipping company and 1st grade agencies directly.

Q: What's your trade term?

We accept FOB, CFR, CIF terms. We're also experienced in mix loading.

If you have any more questions, please don't hesitate to let us know. We will send you more details. Thank you!

Nancy Zhan

Xiamen ZhongJingtai Building Materials Co.,Ltd

Address: Unit 2A, Lianchang Building, No.6-8 Huli Avenue, Huli District, Xiamen, China

Cellphone: +86-592-5216902 Fax: 86-592-5216319

Web: http://zjteps.en.made-in-china.com